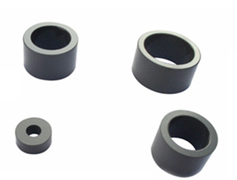

Bonded neodymium magnet

| Performance | BNP-6 | BNP-8L | BNP-8 | BNP-8SR | BNP-8H | BNP-9 | BNP-10 | BNP-11 | BNP-11L | BNP-12L |

| B r T(Gs) | 0.55-0.62 | 0.60-0.64 | 0.62-0.69 | 0.62-0.66 | 0.61-0.65 | 0.65-0.70 | 0.68-0.72 | 0.70-0.74 | 0.70-0.74 | 0.74-0.80 |

| H CB kA/m(kOe) |

285-370 (3.6-4.6) |

360-400 (4.5-5.0) |

385-445 (4.8-5.6) |

410-465 (5.2-5.8) |

410-455 (5.2-5.7) |

400-440 (5.0-5.5) |

420-470 (5.3-5.9) |

445-480 (5.6-6.0) |

400-440 (5.0-5.5) |

420-455 (5.3-5.7) |

| H CJ kA/m(kOe) |

600-755 (7.5-9.5) |

715-800 (9-10) |

640-800 (8-10) |

880-1120 (11-14) |

1190-1440 (15-18) |

640-800 (8-10) |

640-800 (8-10) |

680-800 (8.5-10) |

520-640 (6.5-8) |

520-600 (6.5-7.5) |

| (BH) max kJ/m 3 (MGOe) |

44-56 (5.5-7) |

56-64 (7.0-8.0) |

64-72 (8.0-9.0) |

64-72 (8.0-9.0) |

64-72 (8.0-9.0) |

70-76 (8.8-9.5) |

76-84 (9.5-10.5) |

80-88 (10.0-11.0) |

78-84 (9.8-10.5) |

84-92 (10.5-11.5) |

| D g/cm 3 | 5.5-6.1 | 5.6-6.1 | 5.8-6.1 | 5.8-6.1 | 5.9-6.2 | 5.8-6.1 | 5.8-6.1 | 5.8-6.1 | 5.8-6.1 | 5.8-6.1 |

| μ r | 1.15 | 1.15 | 1.15 | 1.13 | 1.15 | 1.22 | 1.22 | 1.22 | 1.26 | 1.26 |

| α(Br) %/ ℃ | -0.13 | -0.13 | -0.13 | -0.13 | -0.07 | -0.12 | -0.11 | -0.11 | -0.11 | -0.08 |

| T w ℃ | 100 | 100 | 120 | 150 | 125 | 120 | 120 | 120 | 110 | 110 |

| Performance | BNI-3 | BNI-4 | BNI-5 | BNI-6 | BNI-6H | BNI-7 | BNI-5SR(PPS) |

| B r T (Gs) | 0.2-0.4 | 0.40-0.46 | 0.45-0.51 | 0.51-0.56 | 0.48-0.56 | 0.54-0.64 | 0.45-0.50 |

| H CB kA/m(kOe) |

120-240 (1.5-3.0) |

250-335 (3.1-4.2) |

280-360 (3.5-4.5) |

295-375 (3.7-4.7) |

335-400 (4.2-5.0) |

320-400 (4.0-5.0) |

300-360 (3.8-4.5) |

| H CJ kA/m(kOe) |

480-640 (6.0-8.0) |

575-735 (7.2-9.2) |

640-800 (8-10) |

640-800 (8-10) |

1035-1355 (13-17) |

640-800 (8-10) |

875-1115 (11-14) |

| (BH)max kJ/m 3 (MGOe) |

8-24 (1.0-3.0) |

28-36 (3.5-4.5) |

37-44 (4.6-5.5) |

44-52 (5.5-6.5) |

40-52 (5.0-6.5) |

51-59 (6.5-7.5) |

36-44 (4.5-5.5) |

| D g/cm 3 | 3.9-4.4 | 4.2-4.9 | 4.5-5.0 | 4.7-5.1 | 4.8-5.2 | 5.0-5.5 | 4.9-5.4 |

| μ r | 1.2 | 1.2 | 1.2 | 1.13 | 1.13 | 1.13 | 1.13 |

| α(Br) %/℃ | -0.15 | -0.13 | -0.13 | -0.11 | -0.15 | -0.11 | -0.13 |

| Tw℃ | 100 | 110 | 120 | 120 | 130 | 120 | 150 |

Bond neodymium magnets is made of neodymium powder and adhesive. Usually, bonded neodymium magnet make epoxy coating to be anti-corrosion;

Application of Bonded neodymium magnet

Bonded neodymium ring magnets are mainly used for small motors, metering equipment, machinery, audio-visual equipment, instrumentation, CD-ROM, DVD-ROM drive motor, the hard drive spindle motor HDD, other micro DC motors and automation instrumentation and so on. At present, our company has supplied customers with magnets used on air conditioning motor, vacuum cleaner pump, automotive exhaust treatment device, brushless motor, mobile phone and so on.

You are welcome to contact us and provide magnet information including size, tolerance, grade or performance, coating, magnetization direction and other requirements; please don't forget the drawing if the shape is complicated. We will deal with your inquiry soon.

中文

中文 ENGLISH

ENGLISH