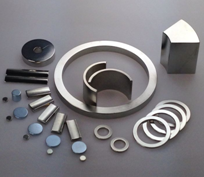

Sintered Neodymium Magnet

Physical Properties

| Grade | Br | Hcb | Hcj | BH(max) | The max working temp. |

| mT(KG) | KA/m(KOe) | KA/m(KOe) | KJ/m3(MGOe) | ℃ | |

| N35 | 1170-1220(11.7-12.2) | ≥868(≥10.9) | ≥955(≥12) | 263-287(33-36) | <80 |

| N38 | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥955(≥12) | 287-310(36-39) | <80 |

| N40 | 1250-1280(12.5-12.8) | ≥907(≥11.4) | ≥955(≥12) | 302-326(38-41) | <80 |

| N42 | 1280-1320(12.8-13.2) | ≥915(≥11.5) | ≥955(≥12) | 318-342(40-43) | <80 |

| N45 | 1320-1380(13.2-13.8) | ≥923(≥11.6) | ≥955(≥12) | 342-366(43-46) | <80 |

| N48 | 1380-1420(13.8-14.2) | ≥923(≥11.6) | ≥955(≥12) | 366-390(46-49) | <80 |

| N50 | 1400-1450(14-14.5) | ≥796(≥10) | ≥876(≥11) | 382-406(48-51) | <80 |

| N52 | 1430-1480(14.3-14.8) | ≥796(≥10) | ≥876(≥11) | 398-422(50-53) | <80 |

| 35M | 1170-1220(11.7-12.2) | ≥868(≥10.9) | ≥1114(≥14) | 263-287(33-36) | <100 |

| 38M | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥1114(≥14) | 287-310(36-39) | <100 |

| 40M | 1250-1280(12.5-12.8) | ≥923(≥11.6) | ≥1114(≥14) | 302-326(38-41) | <100 |

| 42M | 1280-1320(12.8-13.2) | ≥955(≥12) | ≥1114(≥14) | 318-342((40-43) | <100 |

| 45M | 1320-1380(13.2-13.8) | ≥995(≥12.5) | ≥1114(≥14) | 342-366(43-46) | <100 |

| 48M | 1360-1430(13.6-14.3) | ≥1027(≥12.9) | ≥1114(≥14) | 366-390(46-49) | <100 |

| 50M | 1400-1450(14.0-14.5) | ≥1033(≥13) | ≥1114(≥14) | 382-406(48-51) | <100 |

| 35H | 1170-1220(11.7-12.2) | ≥868(≥10.9) | ≥1353(≥17) | 263-287(33-36) | <120 |

| 38H | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥1353(≥17) | 287-310(36-39) | <120 |

| 40H | 1250-1280(12.5-12.8) | ≥923(≥11.6) | ≥1353(≥17) | 302-326(38-41) | <120 |

| 42H | 1280-1320(12.8-13.2) | ≥955(≥12) | ≥1353(≥17) | 318-342(40-43) | <120 |

| 44H | 1320-1380(13.2-13.8) | ≥955(≥12) | ≥1353(≥17) | 342-366(43-46) | <120 |

| 48H | 1370-1430(13.7-14.3) | ≥995(≥12.5) | ≥1353(≥17) | 366-390(46-49) | <120 |

| 33SH | 1130-1170(11.3-11.7) | ≥844(≥10.6) | ≥1592(≥20) | 247-271(31-34) | <150 |

| 35SH | 1170-1220(11.7-12.2) | ≥876(≥11.0) | ≥1592(≥20) | 263-287(33-36) | <150 |

| 38SH | 1220-1250(12.2-12.5) | ≥907(≥11.4) | ≥1592(≥20) | 287-310(36-39) | <150 |

| 40SH | 1240-1280(12.4-12.8) | ≥939(≥11.8) | ≥1592(≥20) | 302-326(38-41) | <150 |

| 42SH | 1280-1320(12.8-13.2) | ≥987(≥12.4) | ≥1592(≥20) | 318-342(40-43) | <150 |

| 45SH | 1320-1380(13.2-13.8) | ≥1003(≥12.6) | ≥1592(≥20) | 342-366(43-46) | <150 |

| 28UH | 1020-1080(10.2-10.8) | ≥764(≥9.6) | ≥1990(≥25) | 207-231(26-29) | <180 |

| 30UH | 1080-1130(10.8-11.3) | ≥812(≥10.2) | ≥1990(≥25) | 223-247(28-31) | <180 |

| 33UH | 1130-1170(11.3-11.7) | ≥852(≥10.7) | ≥1990(≥25) | 247-271(31-34) | <180 |

| 35UH | 1180-1220(11.8-12.2) | ≥860(≥10.8) | ≥1990(≥25) | 263-287(33-36) | <180 |

| 38UH | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥1990(≥25) | 287-310(36-39) | <180 |

| 40UH | 1240-1280(12.4-12.8) | ≥899(≥11.3) | ≥1990(≥25) | 302-326(38-41) | <180 |

| 28EH | 1040-1090(10.4-10.9) | ≥780(≥9.8) | ≥2388(≥30) | 207-231(26-29) | <200 |

| 30EH | 1080-1130(10.8-11.3) | ≥812(≥10.2) | ≥2388(≥30) | 223-247(28-31) | <200 |

| 33EH | 1130-1170(11.3-11.7) | ≥836(≥10.5) | ≥2388(≥30) | 247-271(31-34) | <200 |

| 35EH | 1170-1220(11.7-12.2) | ≥876(≥11.0) | ≥2388(≥30) | 263-287(33-36) | <200 |

| 38EH | 1220-1250(12.2-12.5) | ≥899(≥11.3) | ≥2388(≥30) | 287-310(36-39) | <200 |

The above mentioned grades are our basic grades. We also have T and L-T series, which are derived from these basic grades. The main properties of the derived grades such as Br、Hcj、Hcb and BH(max) are corresponding to those basic grades, while other properties are different.

Plating

| Type | Color | Mini.thickness(um) | Rusting time | bonding force(Mpa) | working temp.(℃) | ||

| SST | humidity heat test | PCT | |||||

| Ni(barrel) | silver | 10 | 72 | 300 | 48 | 1-5 | <200 |

| Ni(rack) | silver | 10 | 16 | 300 | 48 | ||

| NiCuNi(barrel) | silver | 10 | 72 | 500 | 48 | ||

| NiCuni(rack) | silver | 10 | 16 | 500 | 48 | ||

| White Zn | white | 4 | 24 | 48 | / | 2-8 | <70 |

| CZn | color | 6 | 48 | 48 | / | ||

| Ni+Sn | silver white | 12 | 72 | 500 | 96 | 1-5 | 15-160 |

| Ni+Ag | silver | 12 | 72 | 500 | 96 | <160 | |

| Ni+Cu | golden | 12 | 72 | 500 | 96 | <160 | |

| Epoxy | black | 10 | 48 | 48 | 120 | 3-10 | <130 |

| grey | 10 | 48 | 48 | 120 | |||

| Passivate | 3-5 | ||||||

Application

Sintered NdFeB is widely used in the area of industry, automotive, IT, speakers, MRI, Motors, Pumps, Generators, sensors, magnetic seperators and so on.

You are welcome to contact us and provide the detailed information including grade, size, tolerance, coating, magnetic direcion and other requirements. If there is the drawing, please send it to us. We will deal with your inquiry soon.

中文

中文 ENGLISH

ENGLISH